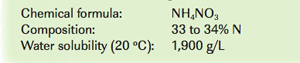

Ammonium nitrate was the first solid nitrogen (N) fertilizer produced on a large scale, but its popularity has declined in recent years. Consequently, Mosaic does not sell ammonium nitrate; the information below is for educational purposes. It’s been a common N source because it contains both nitrate and ammonium, and it has a relatively high nutrient content.

Production

Large-scale production of ammonium nitrate began in the 1940s when it was used for munitions during wartime. After the end of World War II, ammonium nitrate became available as a commercial fertilizer. The production of ammonium nitrate is relatively simple: Ammonia gas is reacted with nitric acid to form a concentrated solution and considerable heat.

Prilled fertilizer forms when a drop of concentrated ammonium nitrate solution (95 percent to 99 percent) falls from a tower and solidifies. Low-density prills are more porous than high-density prills and are preferred for industrial use, while high-density prills are used as fertilizer. Manufacturers produce granular ammonium nitrate by repeatedly spraying the concentrated solution onto small granules in a rotating drum.

Since ammonium nitrate is hygroscopic and therefore readily attracts moisture from air, it’s commonly stored in air-conditioned warehouses or in sealed bags. Manufacturers typically coat the solid fertilizer with an anti-caking compound to prevent sticking and clumping.

Small quantities of carbonate minerals are sometimes added prior to solidifying, which eliminates ammonium nitrate’s explosive properties. These additives lower the N concentration and are sparingly soluble, making the modified product less suitable for application through an irrigation system (fertigation).

Agricultural use

Ammonium nitrate is a popular fertilizer since it provides half of the N in the nitrate form and half in the ammonium form. The nitrate form moves readily with soil water to the roots, where it’s immediately available for plant uptake. The ammonium fraction is taken up by roots or gradually converted to nitrate by soil microorganisms. Many vegetable growers prefer an immediately available nitrate source of plant nutrition and use ammonium nitrate. Animal farmers like it for pasture and hay fertilization since it’s less susceptible to volatilization losses than urea-based fertilizers when left on the soil surface.

Ammonium nitrate is commonly mixed with other fertilizers, but these mixtures can’t be stored for long periods because of a tendency to absorb moisture from the air. The very high solubility of ammonium nitrate makes it well suited for making solutions for fertigation or foliar sprays.

Management practices

Easy handling and high nutrient content make ammonium nitrate a popular N fertilizer It’s also very soluble in the soil, and the nitrate portion can move beyond the root zone under wet conditions. Nitrate can also be converted to nitrous oxide gas in very wet conditions through the process of denitrification. The ammonium portion isn’t subject to considerable loss until it’s oxidized to nitrate.

Concerns over illegal use of this fertilizer for explosives have caused strict government regulation in many parts of the world. Restrictions on sales and transportation have caused some fertilizer dealers to discontinue handling this material.

Non-agricultural uses

A low-density form of prilled ammonium nitrate is widely used as an explosive in the mining industry and on construction sites. Manufacturers intentionally make it porous to allow rapid adsorption of fuel oil (termed “ANFO”).

Instant cold packs are made with two bags—one containing dry ammonium nitrate and the second containing water. When the barrier separating the bags is ruptured, the ammonium nitrate rapidly dissolves in an endothermic reaction, lowering the pack’s temperature to 2 to 3 degrees Celsius within a very short time.

Source: Nutrient Source Specifics, No. 22, International Plant Nutrition Institute.